Estamos usando cookies para oferecer a melhor experiência em nosso site.

Você pode descobrir mais sobre quais cookies estamos usando ou desativá-los nas configurações.

Maintenance and Calibration Contracts for Multi-Brand Tightening Systems

Direct Sales of Multi-Brand Tightening Systems

Technical Solutions focused on Assembly of Screwed Joints

Sale of Spare Parts with Warehouses in the United States and Brazil

Solutions in Industrial Assembly

Reaction Bar Manufacturing

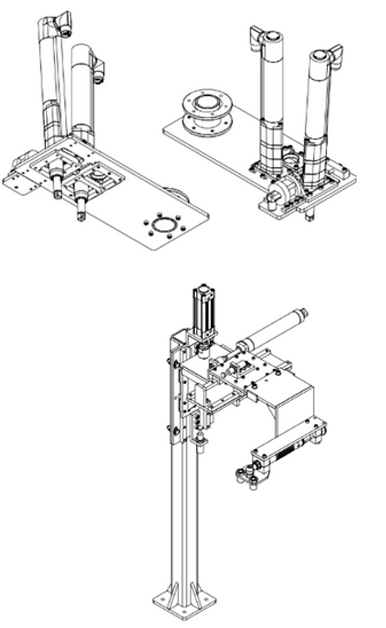

Design and Own Development of Articulated Arms

Manufacturing of Special Sockets for Industrial Applications

Technical Studies for Issuing Mechanical Reports

Device and Jig Manufacturing

Projects and Development of Automation, Assembly Lines, Automated Cells and Automatic Stations

Improvements in Cycle Times, with Gains

Operational and basis in Industry 4.0

Low electrical system projects

voltage, digitalization, IoT, RFID, RTLS

Projects and software development based on PC, Web and Mobile

Improvements in tightening systems, torque strategies and failure prevention

Industrial robots and Cobots

Supervisory Systems: Siemens Automation, Rockwell Automation; Labview Ni + Power B.i Interface

Industrial Networks: DeviceNet, Profibus,

Profinet and Modbus

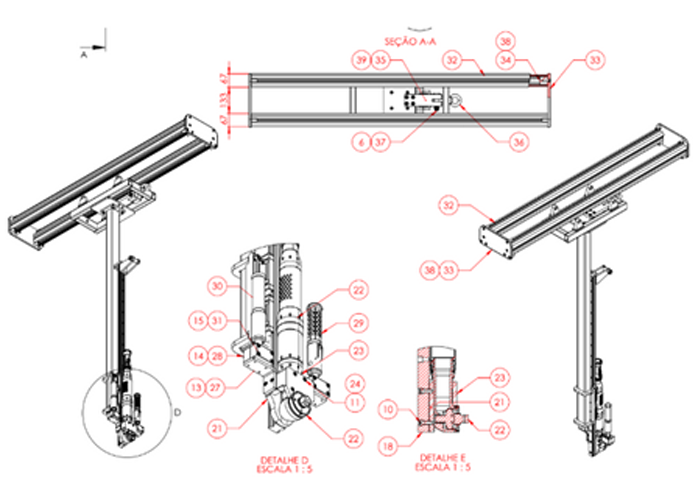

Suspension Line / Stabilizer Bar

Unification of Stabilizer Bar Operation

Reduction of manufacturing costs and

Labor

Third Automatic Variable Spindle

Integration between the Fanuc Robot and Atlas Copco Nurture Machine

Rear Brake Line

Rear Disc Assembly Automation

Reduction in Manufacturing and Labor costs

Pneumatic Movement

Suspension Line / Stabilizer Bar

Unification of Stabilizer Bar Operation

Reduction of manufacturing costs and

Labor

Third Automatic Variable Spindle

Integration between the Fanuc Robot and Atlas Copco Nurture Machine

Rear Brake Line

Rear Disc Assembly Automation

Reduction in Manufacturing and Labor costs

Pneumatic Movement

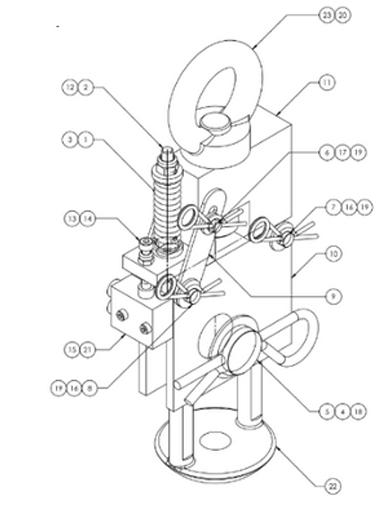

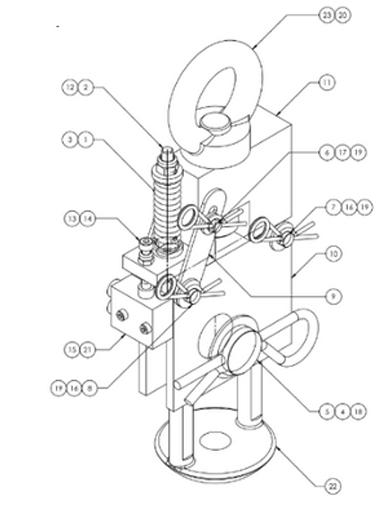

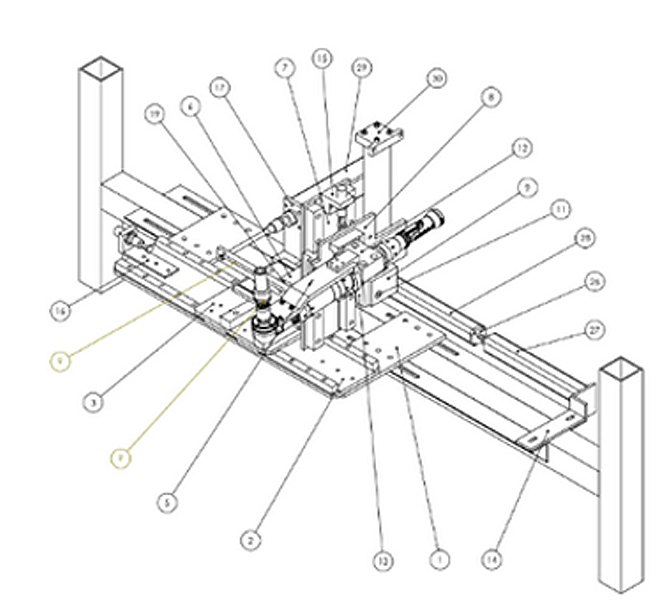

Load Sensor

Bi-Manual Activation

Pneumatic Advancement Through Mechanical Rocker

Vertical Reaction Arm

Development of a Sensor with Pre-defined Load

Error-Proof Device (Poka-Yoke) to Prevent the Product from Falling During Transport

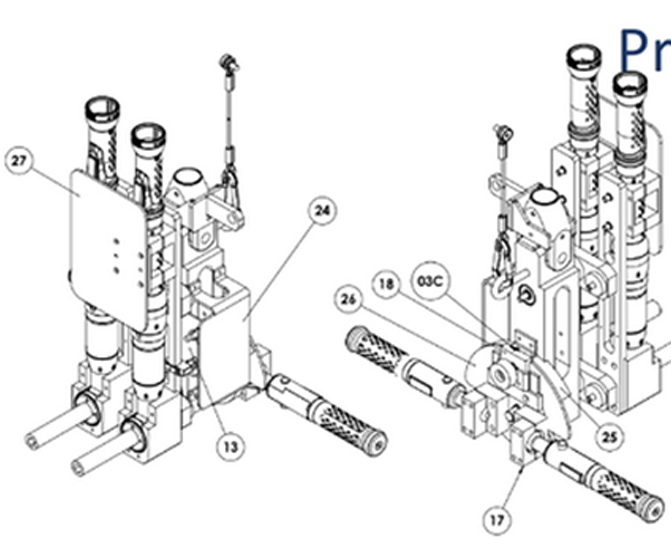

Bi-spindle system with two screwdrivers

Brake System Assembly

Integration with the Atlas Copco Nurture Machine

X, Y, Z System with Pneumatic Advance

Assembly of the Steering Sector

Integration between the Fanuc Robot and the Atlas Copco Nurture Machine

Android Supplier of the Year Award – 2022

Industrial Maintenance/ Commerce and Import

Development of Solutions and Special Projects

Estamos usando cookies para oferecer a melhor experiência em nosso site.

Você pode descobrir mais sobre quais cookies estamos usando ou desativá-los nas configurações.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.